The Class III price moved from $21.67/cwt in August to $19.07/cwt in September, a drop of $2.60/cwt. Although a Class III price above $19/cwt would have been a high price just a few years ago, this is no longer the case with current feed prices.

Income over feed cost will likely be much smaller this fall than what we had during the summer. Dairy producers will have to scrutinize their operation to ensure profitability. Understanding what components of a hundredweight of milk are profitable will be important.

Three assembly lines

A dairy cow is a little bit like an automobile assembly plant with three assembly lines: one line produces the fat, one produces the milk protein and the last one assembles the water with a component called “other solids.”

The other solids contain the lactose (about 4.8 percent of the milk) and ash (about 0.9 percent of the milk). The percentage of other solids in milk doesn’t change much (5.7 percent) because lactose is the primary osmo-regulator — it regulates the osmotic pressure of milk so that the secretory cells in the udder do not burst.

That’s why we conceptualize the third assembly line as a process of assembling the water and the other solids together; we just cannot separate the two.

A standard cow

Every cow is different and so is every herd. But on an average an Ohio cow produces about 70 pounds of milk per day, at 3.6 percent fat, 3.0 percent protein and 5.7 percent other solids. Put differently, our “standard” cow produces 2.52 pounds of fat, 2.10 pounds of protein, 4.06 pounds of other solids and 61.32 pounds of water per day.

Profitable assembly lines

As managers of this assembly plant, we need to calculate the daily revenues and costs of each of our assembly lines. With multiple component pricing, the gross income from each assembly line is calculated using the component prices established by the market administrator based on complex formulas and dairy product prices.

For September, fat was priced at $2.20 per pound, protein at $3.03 per pound, and other solids at $0.41 per pound. The pricing of water would be approximately equal to the producer price differential minus the hauling costs; on an average, these just about cancel each other. So the price of water used in this article is $0.00/cwt.

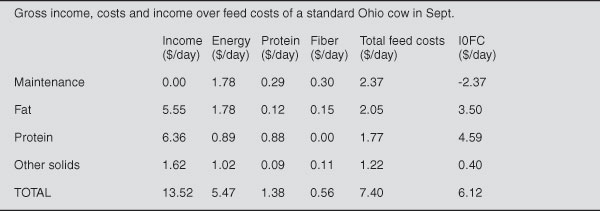

The daily gross revenues from each assembly line are calculated in Table 1.

Assembly line costs

Some costs are incurred on each assembly line. We have to supply the required nutrients for the cow to manufacture and assemble the milk components. Those nutritional requirements are in fact relatively well known.

There is a cost associated with each required nutrient. Ohio State research has found a neat way of determining the cost of each nutrient from feed prices. We have called this the Sesame approach.

In September, dietary energy was costing 16.6 cents per Mcal of net energy for lactation, 28 cents per pound of metabolizable protein, 0.08 cents per pound of effective NDF (the effective fiber, as in the fiber coming from forages) and -0.08 cents per pound of non-effective NDF (the fiber in byproducts).

Table 1 shows the nutritional costs associated with each of the three assembly lines. Also, our factory has overhead costs — those associated with the maintenance of our assembly plant. It takes nutrients to maintain our standard cow, and it currently costs about $2.37 per day in feeds just to maintain this cow.

Where money is made

The income from each component line is obtained by subtracting the nutrient (i.e., feed) costs from the gross income for each line. The fat production line (2.52 pounds of fat per day) is profitable, yielding a net of $3.50 per day.

Protein production (2.10 pounds per day) is even more profitable, with a net of $4.59 per day. The remaining 65 pounds/day (other solids and water) have a very marginal profitability of $0.40 per day. This 40 cents per day would not even cover the overhead cost of $2.37/day to maintain the cow.

Put differently, of the 70 pounds per day of milk shipped, 95 percent of the net revenues are from the 4.6 pounds of fat and protein and only 5 percent are from the 65.4 pounds of water and other solids. Basically, all the money made is on 5 pounds of components. It is almost unfortunate that we have to ship the remaining 65 pounds.

The lesson

How much milk your cows are producing is not very relevant to their profitability. It doesn’t matter much whether they are producing 60, 70 or even 90 pounds per day. What matters is how many pounds of fat and protein they are producing. The rest of the milk is at best a near break-even proposition.

So what is the daily fat and protein production in your herd? Table 1. Gross income, costs, and income over feed costs (IOFC) of a standard Ohio cow in September.

(The author is an Extension dairy specialist at Ohio State University. Questions or comments can be sent in care of Farm and Dairy, P.O. Box 38, Salem, OH 44460.)