Some things were tolerable with $2 corn that are out of the question now that we deal with $7 corn. Undigested grain in the manure is one of them.

Seeds

Corn kernels were not designed to be eaten; they are seeds, and what surrounds the dormant embryo — the endosperm — is there to support the growth of the small plant shortly after germination if the seed is ever put in the right combination of temperature and moisture to allow germination.

These seeds are not designed to be highly digestible when fed to dairy cows. As a feed, whole unprocessed corn kernels don’t make it to the podium of great feeds. It is through its processing that corn gets much of its feeding value to livestock.

Tightly wrapped starch. If you were to look at the endosperm (i.e., the inside of a kernel) through a powerful microscope, you would see that the starch particles are tightly packed in tiny protein bags.

The protein making up the bags is called zein, a protein that is relatively resistant to digestive enzymes.

The rumen microbes in your cows’ rumen have a difficult time breaking open these small bags. Consequently, if the corn you feed your cows with is improperly processed (i.e., the protein bags are not sufficiently busted) then a significant portion of the corn will go through your cows and make for colorful, but money wasting, manure. This is why we have to grind/roll our corn before we feed it.

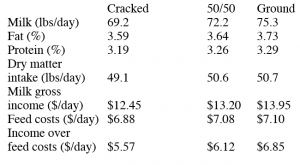

Does it matter? The table shows the results of an experiment that looked at the effect of corn particle size on milk production. This experiment was done more than 10 years ago, but the results would be as applicable today as they were then.

The cracked corn consisted of kernels broken in four to eight particles. The ground corn was a finely ground corn (less than 30 percent retained on a #16 screen — more about this in a minute).

The 50/50 was simply an equal mixture of the two corn types. The economics are calculated using February 2013 milk prices for Order 33 and $0.14/pound of DMI for feed costs.

Using today’s prices, the finely ground corn is worth an extra $1.28/cow per day. You can no longer afford leaving this money on the table.

Managing the grind

You can either purchase a US#16 sieve (the sieve openings are about 1/20 of an inch; NASCO sells some nice ones, although they’re not cheap) or borrow your wife’s flour sifter (I recommend that you buy her a very nice replacement one as opposed to returning her sifter after you have used it with your corn).

If you are feeding ground dry shelled corn, then less than one-third of the corn should be retained on the screen, and most of those particles retained should be less than one-tenth of an inch in diameter. That’s very fine corn; many dairymen are not used to seeing corn ground this fine.

If you are feeding high moisture corn, then the grind is dependent on its moisture. If the moisture is greater than 30 percent then you want nearly all the particles to be greater than one-tenth of an inch.

Between 25 and 30 percent moisture, a quarter of the corn should go through the US16 sieve. Less than 25 percent moisture and two-thirds of the corn should go though the sieve.

Results

Follow these guidelines and you should notice a significant change in the amount of grain in your cows’ manure. If not, something else is the problem. The next thing I would check is your corn silage.

(The author is an Extension dairy specialist at Ohio State University. Questions or comments can be sent in care of Farm and Dairy, P.O. Box 38, Salem, OH 44460.)